Searching

Penberthy

Polymer Eductors

Simple Jet Pump Design offers economical solutions for many complex process operations!

Providing a practical alternative to more complicated and expensive methods. Penberthy jet pumps offer simple more cost-effective ways to pump mix or heat a wide range of liquids in the process industry. Jet pumps can operate with a wide variety of motive liquids and grease. If you recognize any of the following, you can probably use a Penberthy jet pump.

- Injectors

- Educators

- Boosters

- Ejectors

- Kinematic Pumps

- Siphons

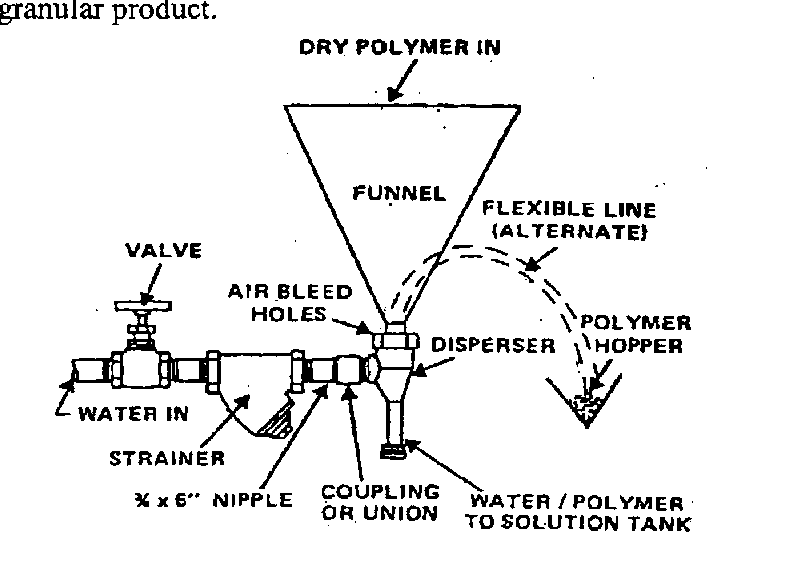

The follwing illustration shows its use with a "dry polymer" but it could be any dry powder or granular products.

Penberthy jet pump may differ in appearance basic operation is the same. Jet pumps also known as educators operate on the principles of fluid dynamics. An operating fluid media which is referred to as the MOTIVE. Place under pressure enters the inlet and is forced through th nozzle where it is converted into a high-velocity stream. This high-velocity stream decreases the pressure in the suction chamber, creating a partial vaccum that draws the suction material into the chamber where is entrained by the MOTIVE MEDIA. Once the SUCTION stream is drawn in. Shear between the motive media and the transported material causes both media to be intermixed and pumped out the DISCHARGE outlet dispelled at a pressure greater than that of the SUCTION stream but lower than that of the MOTIVE. This basic principle of fluid dynamics is what makes the Penberthy Jet Pumps work.

Motive:

This fuction is the power phase of the pumping operation. At this stage the velocity of the motive media increases as through a nozzle. This phase of the pumping operation just takes advantage of the Kinetic properties of the motive media, weather it is a liquid stream or gas.

Suction:

This connection of the jet pump is where the pumping action takes place. The high vilocity stream of the motive causes a drop in pressure in the suction chamber. This allows pressure in the suction vessel to push a liquid, steam or gas into the suction chamber of the jet pump. This in turn, is entrained by the high-velocity motive stream emerging from the inlet nozzle.

Discharge:

As it combines with the suction media, some kinetic energy of the motive is transferred to the SUCTION, mixing discharging at a reduced pressure. The amount of pressure that can be recovered depends on the ration of MOTIVE flow to SUCTION flow plus the amount of SUCTION pressure built up in the suction vessel.