Searching

BioReactor

Systems for Industrial Application

Eliminate Surcharges on Waste Water

- Modular systems to handle almost any flow rate

- Fluidized bed (large surface area)

- Solids removal capabilities

- Uses naturally occuring microorganism's to consume organic pollutants

- Low maintenance system

- Minimal energy requirements (typically no blower system needed)

Industrial Wastewater Treatment

AQUAMARK is now applying modular, pre-engineered water technology to industrial wastewater applications. The water treatment processes and technologies utilized in aquaculture systems are identical to those used to purify industrial wastewater, only the application differs. A combination of 'Couble Drain' tanks can be used for primary skimming of floatable oil and grease and separation of settle able solids. The Bio-Reactor is used to culture naturally occuring micro-organisms which remove dissolved organic compounds from wastewater.

It has been found that naturally occurring micro-organisms readily colonize sufaces which are in regular contact with organic wastes such as pipe and tank walls and drains, they utilize the organic waste streams as "food", and once the wastes have been present at a location for a period of time, robust, complex, communities of micro-organisms are simply collected and inoculated into the Bio-Reactor so that there is no need for elaborate or expensive artificial inoculants. The Bio-Reactor is designed to provide an optimized environment for culturing enormous quantities of the naturally occurring, waste consuming micro-organisms already established on site. The Bio-Reactor is sized for a given installation to provide enough surface area to culture sufficient micro-organisms to consume the organic wastes from the wastewater stream.

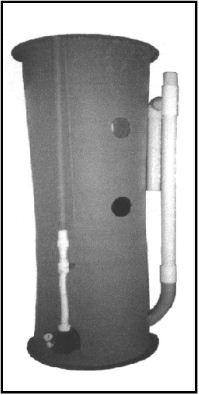

The Bio-Reactor

This new compact, high efficiency Bio-Reactor has been developed through an extensive on-going. twenty tyear R&D program (U.S. patent #'s 5,055,186 & Canadian #'s 557,035 and 617,071)

The reactor utilizes a custom configured, floating, pelleted plastic media to provide an enormous surface area (500 fl3/ft.3) for culturing the micro-organisms which digest and remove a wide range of organic contaminants from wastewater. An innovative Revolving injector system, regularly and uniformly distributes the wastewater throughout the filter bed. The injected wastewater fluidizes (stirs) only a narrow zone of media at any given time which conserves energy. The fluidization shears off excess bio-film (micro-organisms) which promotes growth of a stable healthy colony for optimum waste removal.The injector system is powered simply by the flow of incoming wastewater. The Bio-Reactor design is much more compact that concentional wastewater systems because of it's unique media and the self cleaning, simple desigh results in sustained, virtually maintenance free operation. Additionally, the cone bottomed base of the cylindrical bio-reactor is designed to collect and concentrate particulate wastes and excess sheared bio-film from where they are periodically removed through a valve outlet.